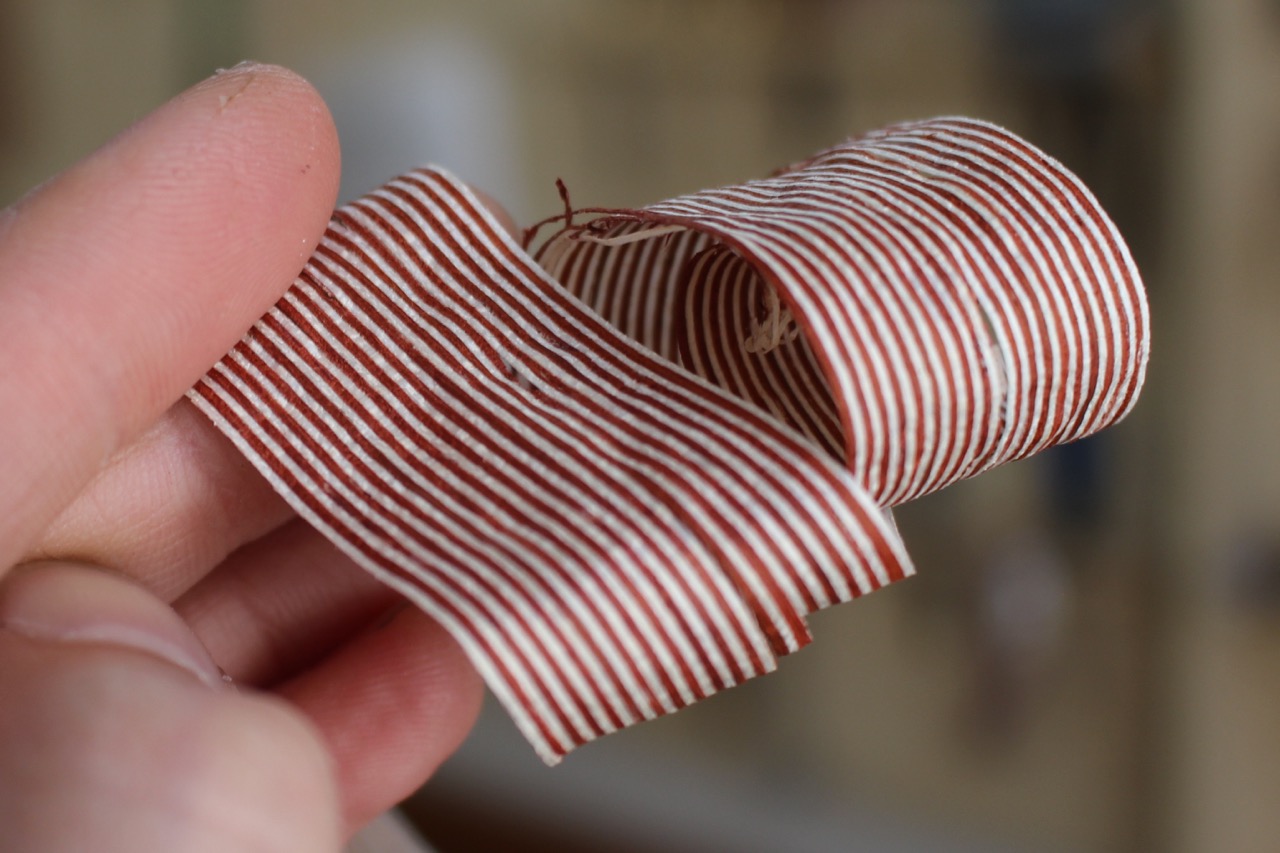

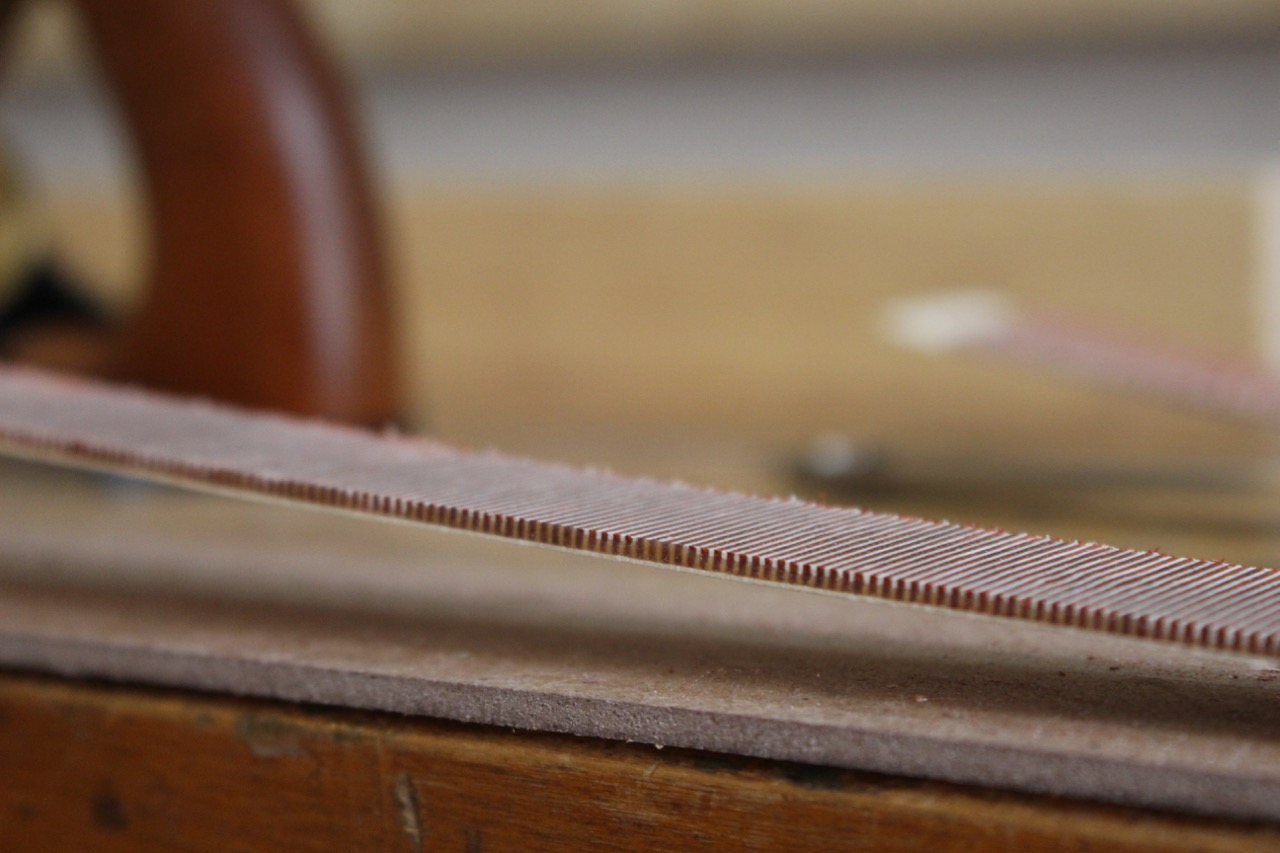

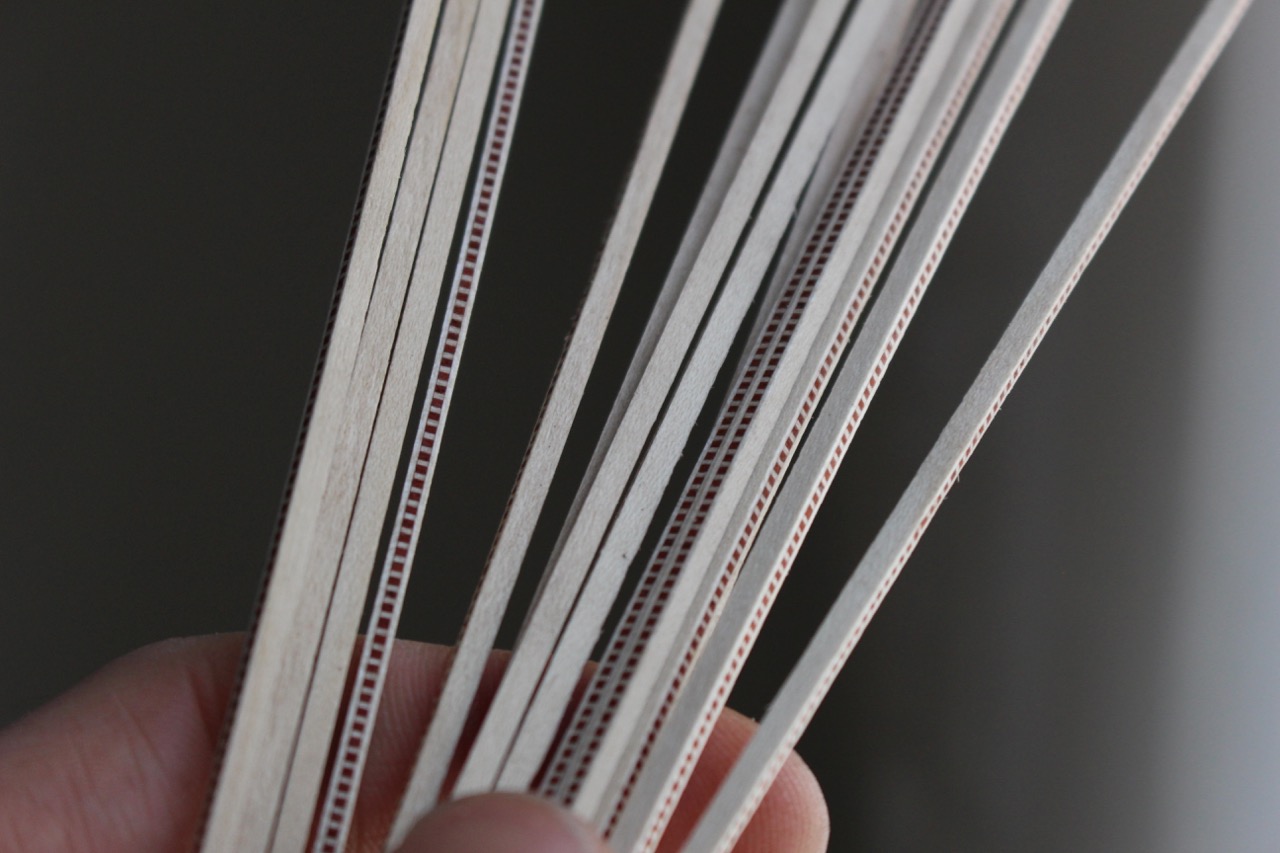

I've tried to document the process in a bit more detail that usual of making the ladder motif that is used in many rosettes including my Torres model. The process is simple in idea, but somewhat tedious in execution. For this particular lay-up of veneers, I'm using padouk and sycamore. From my last blog post you can see the first stack of veneers cut and piled up prior to gluing. After the glue dries, I calculate the number of cuts necessary to end up with the correct final length to use in the outermost and largest ring of my rosette. I stack the subsequent blocks and glue them again into a long strip. After that, I plane all sides of the log and take care to keep everything parallel and square. I then glue a long strip of veneer along the end grain sides. Once the glue dries, I cut these strips off, plane the fresh side of end grain to the final thickness and glue another strip of veneer. Finally, I slice off strips with a knife and clean them up with a plane. The hardest part is planing the end grain by hand to a consistent width within the tolerance of a thousandth of an inch, so that when all is said and done, the side grain is on display which results in cleaner lines and more reflective figure.